Our mission is Together, we look forward to mutual growth and a bright future of cooperation!

Contact us for more sample, According to your needs, customize for you.

inquiry nowThe Difference Between ADSS Cable Aramid and Polyester Yarn

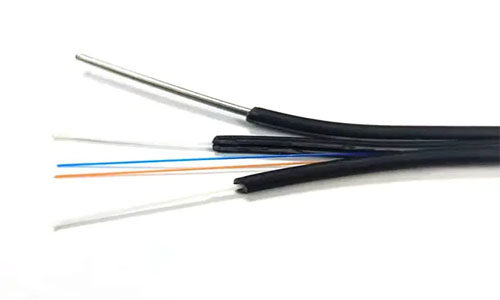

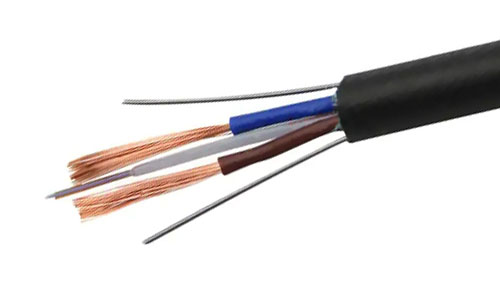

The difference between ADSS (All-Dielectric Self-Supporting) cable with Aramid and Polyester yarn lies primarily in their respective properties and roles within the cable structure:

Material Properties:

Aramid: Aramid fibers, such as Kevlar, are known for their exceptional strength-to-weight ratio and resistance to stretching. They provide high tensile strength and durability, making them ideal for bearing the mechanical loads experienced by the cable during installation, tensioning, and operation.

Polyester: Polyester yarn offers flexibility, elasticity, and abrasion resistance. While not as strong as Aramid, Polyester adds resilience to the cable and helps improve its handling characteristics. It also contributes to the cable's resistance to environmental factors like moisture and temperature fluctuations.

Role in Cable Structure:

Aramid: Aramid fibers are typically used as the primary strength members within the cable. They provide structural support and ensure the cable can withstand the mechanical stresses associated with its installation and operation. Aramid fibers bear the majority of the tension load and help maintain the cable's integrity over time.

Polyester: Polyester yarn complements the Aramid fibers by enhancing the cable's flexibility and resistance to abrasion. Polyester yarn is often used in the cable's outer layers or as additional reinforcing elements to improve handling and protect against damage during installation and maintenance activities.

Applications:

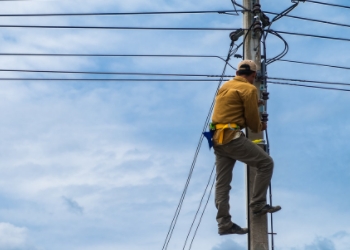

ADSS cables with Aramid and Polyester yarn are commonly used in telecommunications and power distribution networks for long-span aerial installations. They are designed to support their weight and transmit signals without the need for separate metallic support structures.

The specific composition of Aramid and Polyester yarn can vary based on factors such as the cable's design requirements, environmental conditions, and performance specifications.

In summary, while both Aramid and Polyester yarn contribute to the overall performance and durability of ADSS cables, they serve distinct roles within the cable structure. Aramid provides strength and stability, while Polyester enhances flexibility and protection against abrasion, resulting in a cable that can reliably transmit signals over long distances in diverse environmental conditions.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

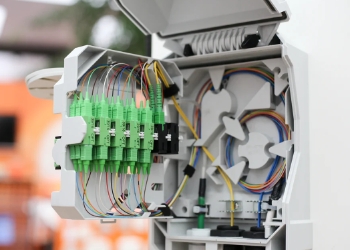

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs