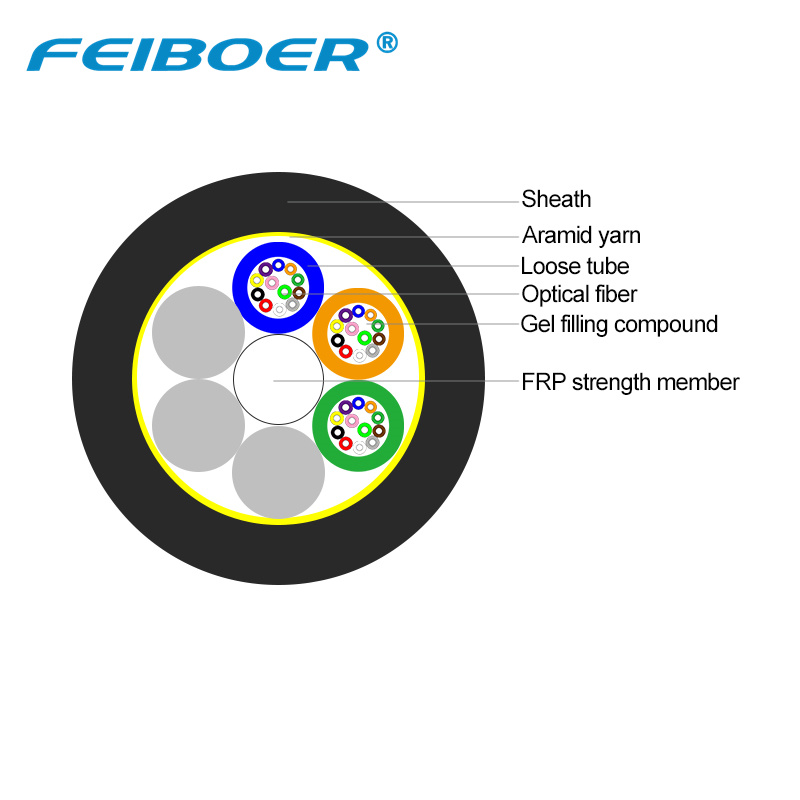

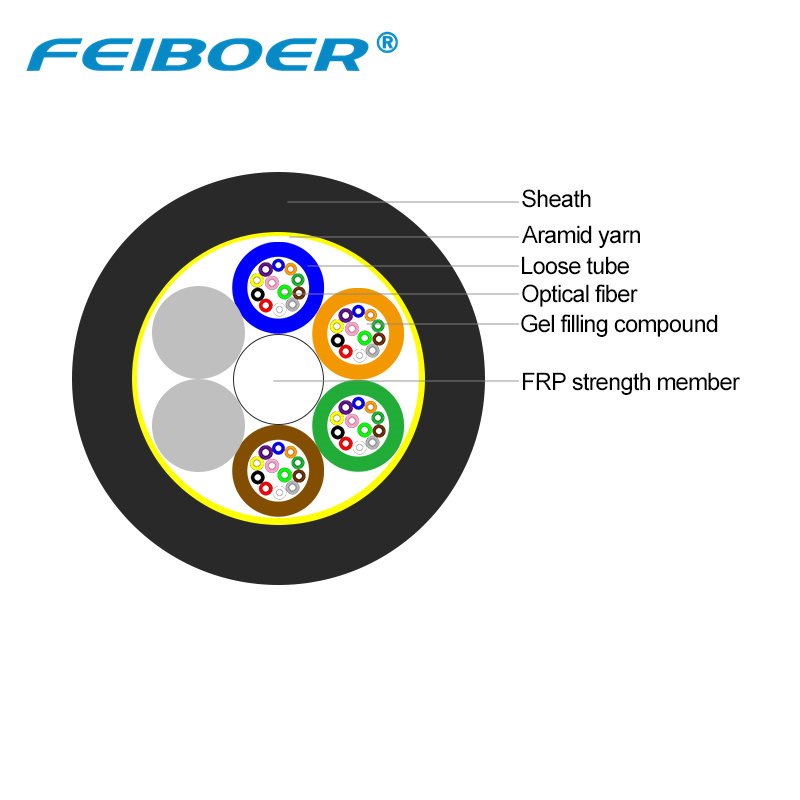

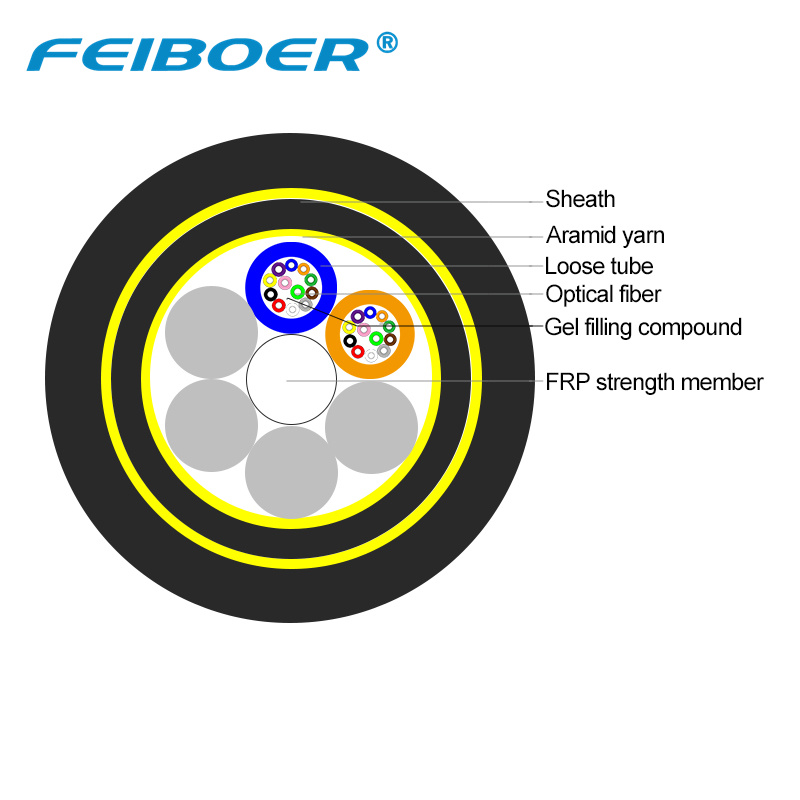

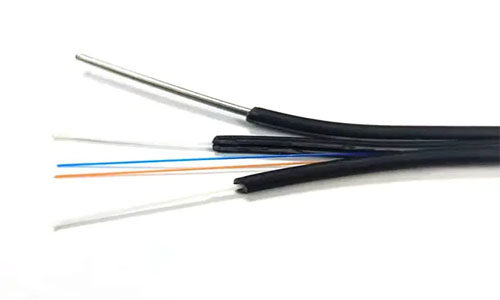

All Dielectric Self-supporting

(ADSS) Optic Cable

(ADSS) Optic Cable

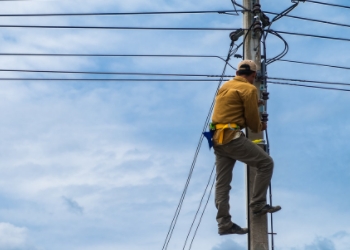

The installation of ADSS (All-Dielectric Self-Supporting) fiber optic cables is a crucial step in establishing a reliable and high-performance communication network. ADSS cables are widely used in various applications, including telecommunications, internet services, and cable television. To ensure the longevity and efficiency of the network, it is essential to follow a precise and meticulous installation process. This professional passage will guide you through the steps required to properly install ADSS fiber cable.

Step 1: Site Survey and Planning

Before commencing the installation, conduct a thorough site survey to assess the terrain, environmental conditions, and potential obstructions. Identify suitable routes for the cable that avoid obstacles such as trees, buildings, and power lines. Plan the cable placement carefully, considering factors like cable sag and tension, to ensure optimal performance and safety.

Step 2: Safety Precautions

Safety should be a top priority during ADSS fiber cable installation. Ensure that the installation team is equipped with appropriate personal protective equipment (PPE), including helmets, gloves, and safety harnesses. Also, adhere to safety regulations and guidelines, especially when working near high-voltage power lines.

Step 3: Cable Handling and Storage

Handle ADSS fiber cable with care to prevent damage. Avoid bending the cable beyond its recommended minimum bend radius, and never exceed its maximum pulling tension. Store the cable in a clean, dry, and temperature-controlled environment to maintain its integrity.

Step 4: Installation Equipment

Prepare the necessary installation equipment, including tensioning equipment, cable rollers, pulling grips, and winches. Ensure that all equipment is in good working condition and regularly inspected for safety and efficiency.

Step 5: Cable Installation

a. Cable Preparation: Unroll and inspect the cable for any visible defects. Attach pulling grips to the cable securely.

b. Tensioning: Maintain proper tension during installation to prevent sagging and ensure the cable follows the desired path. Use a tension meter to monitor and adjust tension as needed.

c. Cable Routing: Route the cable along the planned path, using cable rollers to minimize friction and potential damage. Pay attention to bends and curves, ensuring they are within the recommended bend radius.

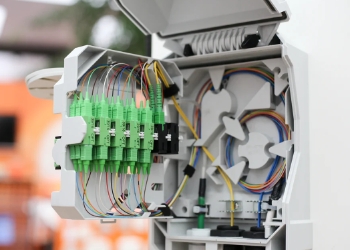

d. Splice Enclosures: Install splice enclosures at designated intervals to facilitate future maintenance and repair. Properly seal and protect splices from moisture and environmental factors.

e. Grounding: Implement a proper grounding system to protect the cable and network equipment from lightning and electrical surges.

Step 6: Documentation and Testing

Maintain comprehensive documentation throughout the installation process. Record cable lengths, splice locations, and any deviations from the original plan. After installation, conduct rigorous testing to verify the integrity and performance of the fiber optic network.

Step 7: Ongoing Maintenance

Regularly inspect and maintain the ADSS fiber cable network to ensure its continued reliability. Periodic checks, cleaning, and preventive measures will extend the lifespan of the cable and optimize network performance.

Properly installing ADSS fiber cable is a critical task that requires meticulous planning, adherence to safety guidelines, and careful execution. By following these professional guidelines, network installers can ensure the long-term reliability and efficiency of the communication network, ultimately benefiting both service providers and end-users.

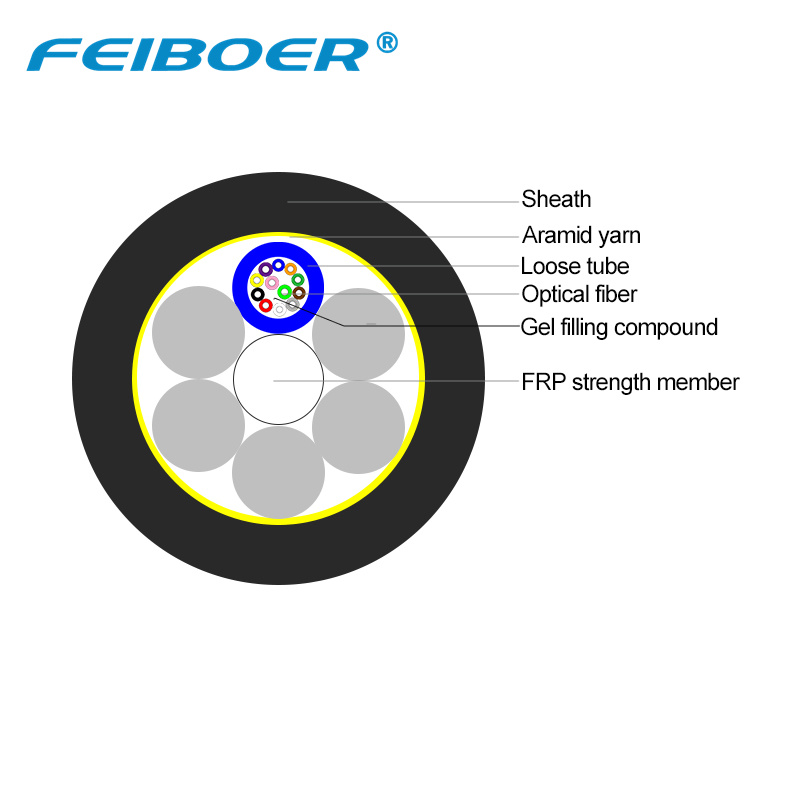

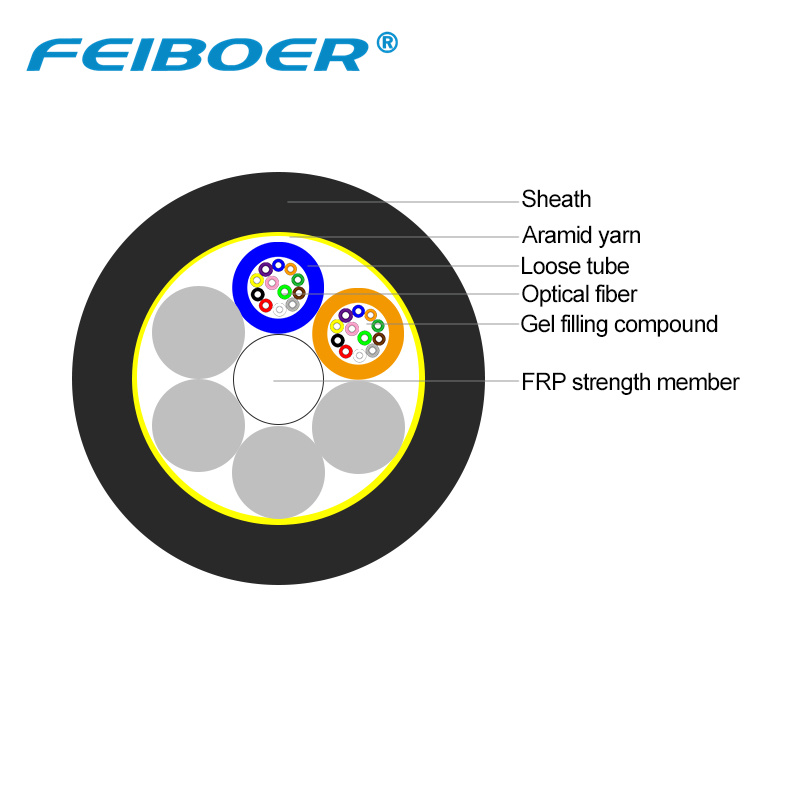

Fiber Optic Cable Customization Can Be Easy & Safe

No matter what structure of fiber optic cable you want, based on our extensive experience, we can manufacture it. In particular, our production lines supports color stripe on the out sheath of the fiber optic cable, which makes the final product can be distinguished from the vast majority of fiber optic cable on the market.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

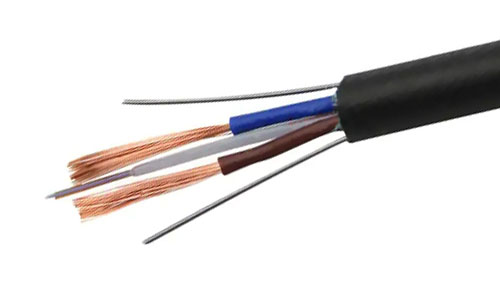

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs