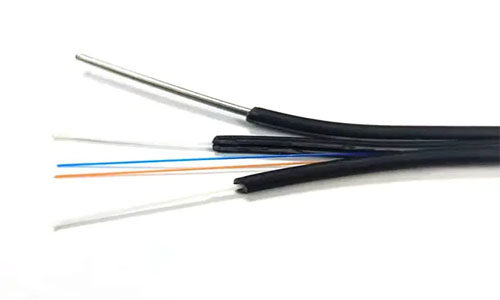

All Dielectric Self Supporting (ADSS) Cable

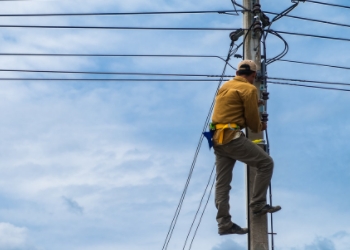

All-dielectric self-supporting cable

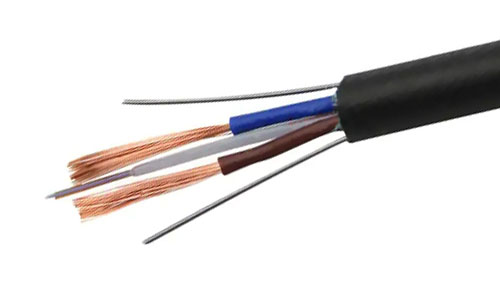

ADSS Fiber Optic Cable

ADSS FIBER CABLE

All-dielectric self-supporting cable

ADSS Cable Quality Certification

Every products have to pass multiple testing instruments before they leave the factory, and they must be accurately tested to ensure that the quality of each product is fully up to standard. We are proud to share that our company and manufacture facilities are recognized by different organizations.

We take our certifications seriously and work hard to keep our products and manufacturing processes up to date and in line with the highest international standards. With our fiber optic solutions certified with ISO 9001, CE, and RoHS, our customers can rest assured that they are acquiring high-quality, safe, and environmentally friendly fiber optic solutions.

View More-

Feel free to contact us to learn more about the benefits of becoming ourdistributor. We will be happy to answer your questions and provide you with moreinformation.

-

Our strong tradition of problem solving and hard work sets the standard for us and helps us become leaders. We do this through a continuous focus on innovation and product development. We always keep the needs of our customers in mind. Always win with quality, always provide the best service. This is to meet the needs and requirements of our customers, both on the business side and on the operational side.

Join Us For Common Development

Contact Us For Best Would you Like to Know more We can Give you the answer

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

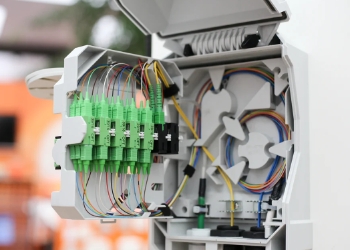

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs