| Fiber Type | G.652 | G.655 | 50/125μm | 62.5/125μm | |

| Attenuation (+20℃) | 850 nm | ≤3.0 dB/km | ≤3.3 dB/km | ||

| 1300 nm | ≤1.0 dB/km | ≤1.0 dB/km | |||

| 1310 nm | ≤0.36 dB/km | ≤0.40 dB/km | |||

| 1550 nm | ≤0.22 dB/km | ≤0.23 dB/km | |||

| Bandwidth | 850 nm | ≥500 MHz-km | ≥200 Mhz-km | ||

| 1300 nm | ≥500 MHz-km | ≥500 Mhz-km | |||

| Numerical Aperture | 0.200±0.015 NA | 0.275±0.015 NA | |||

| Cable Cut-off Wavelength λcc | ≤1260 nm | ≤1450 nm | |||

|

Ref. Outer Diameter(mm) |

Ref. Weight(kg/km) | Rec. Daily Maximum Working Tension(kN) | Maximum Allowable Working Tension(kN) | Break Force(kN) | Strength Member ASC (mm²) | Modulus of Elasticity CSA (kN/mm²) | Heat Expansion Coefficient (x10⁶/K) |

Suitable Span (NESC Standard,m) |

||||

| PE Sheath | AT Sheath | A | B | C | D | |||||||

| 9.5 | 110 | 120 | 1.0 | 2.5 | 8 | 3.0 | 6.6 | 2.1 | 120 | 80 | 100 | 80 |

| 10.0 | 115 | 125 | 1.5 | 4 | 10 | 4.5 | 7.3 | 1.8 | 180 | 120 | 150 | 120 |

| 10.5 | 120 | 130 | 2.5 | 6 | 15 | 7.5 | 8.3 | 1.5 | 250 | 150 | 290 | 150 |

Note: Only part of ADSS cables are listed in the table. ADSS cables with other spans can be requested directly from Feiboer. The specifications in the table are obtained on the condition that there is no difference in height and that the sag of the installation is 1% .The number of fibers is from 2 to 144. The identification of fibers is in accordance with the national standard. This technical sheet can only be a reference but not an addition to the contract, please contact our for more information .

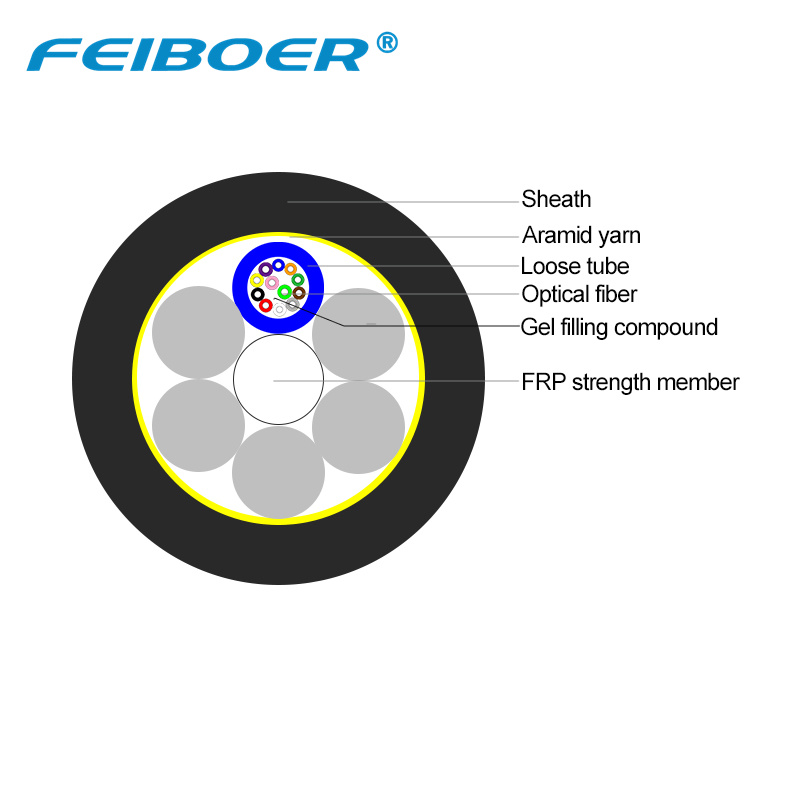

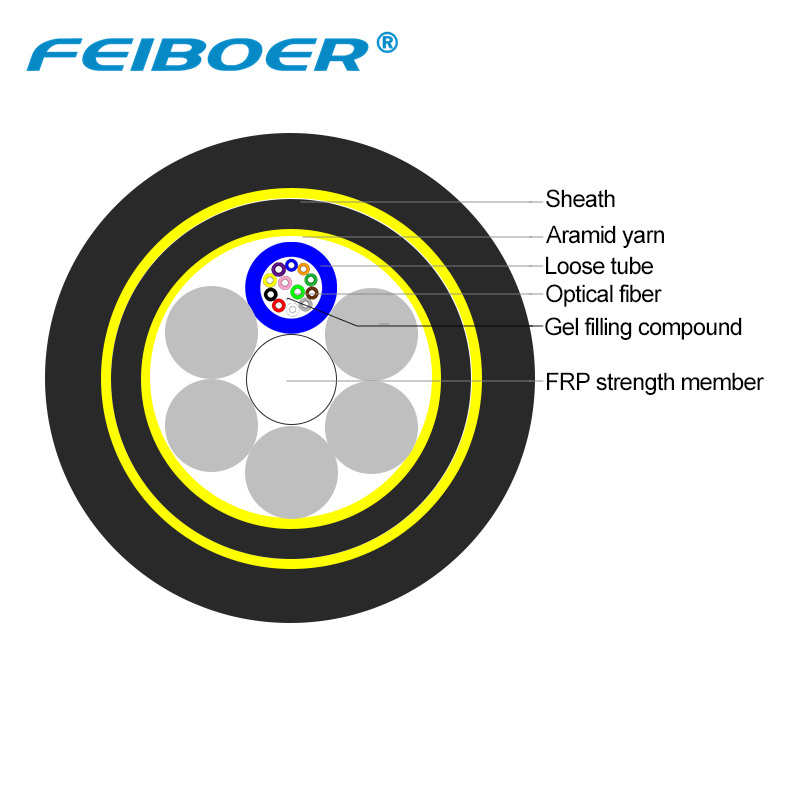

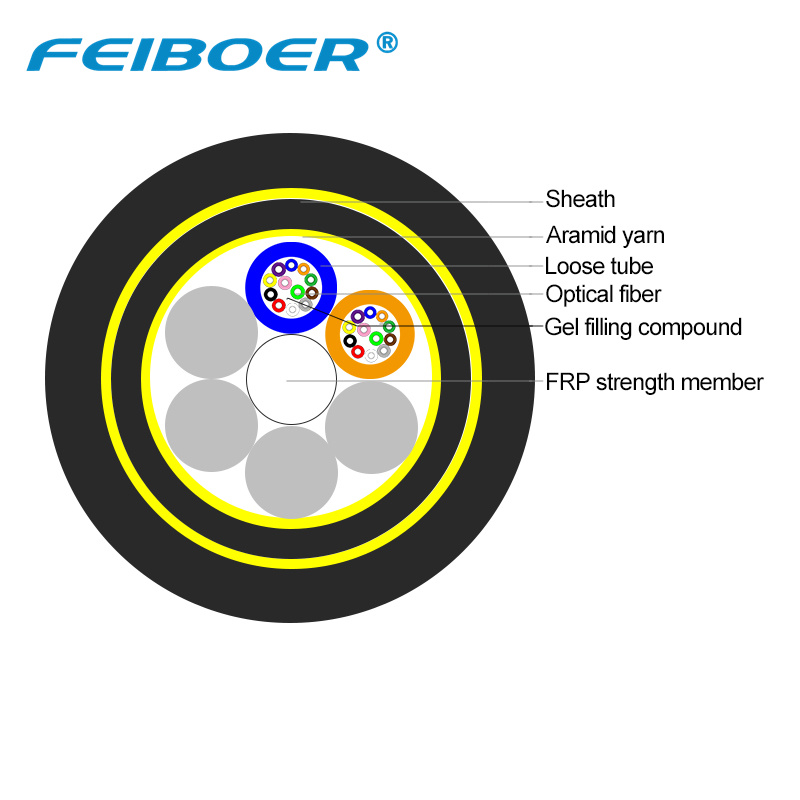

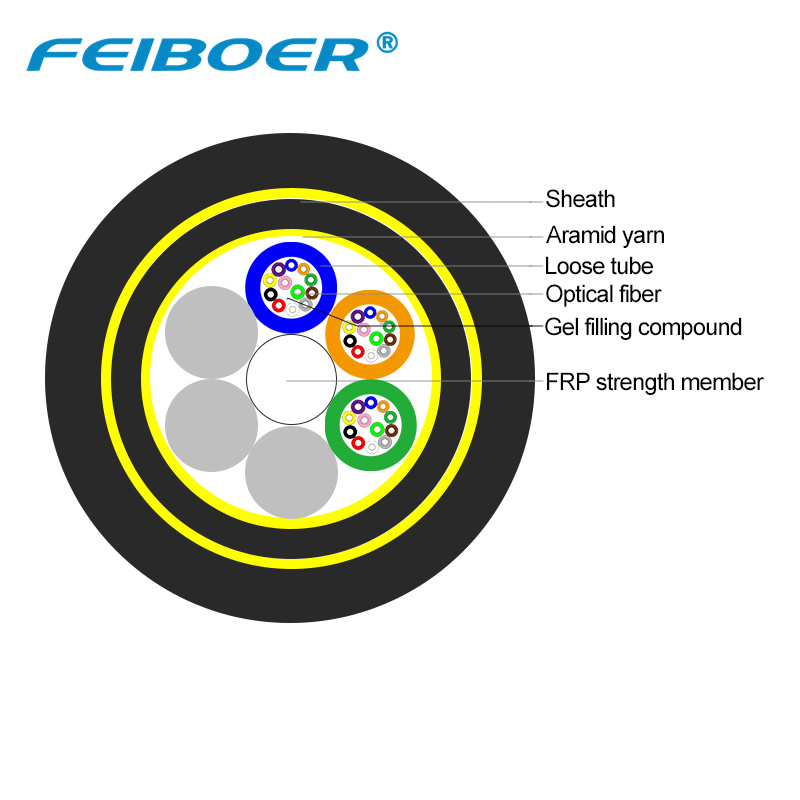

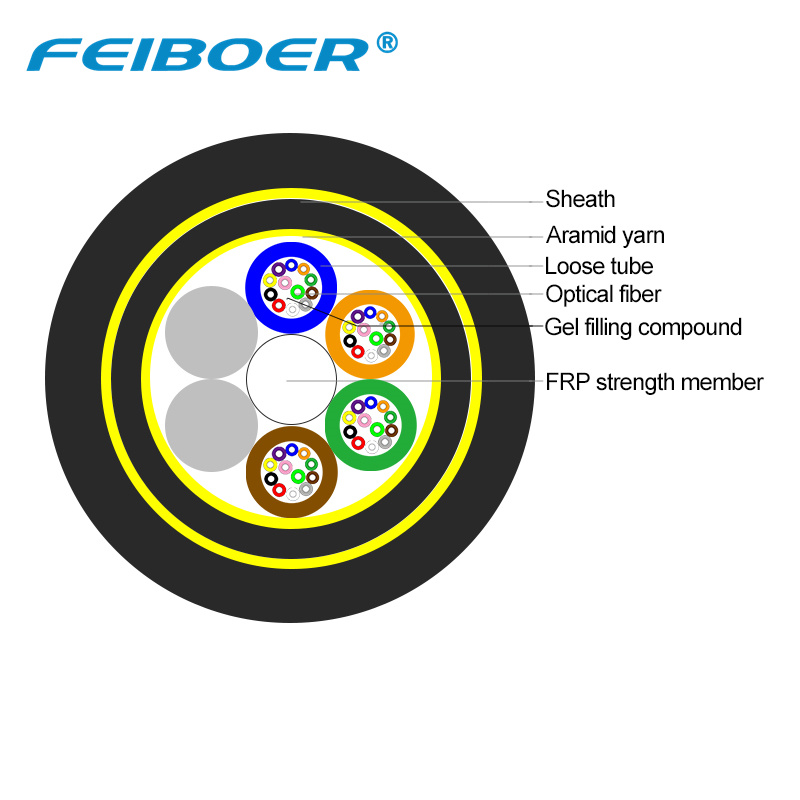

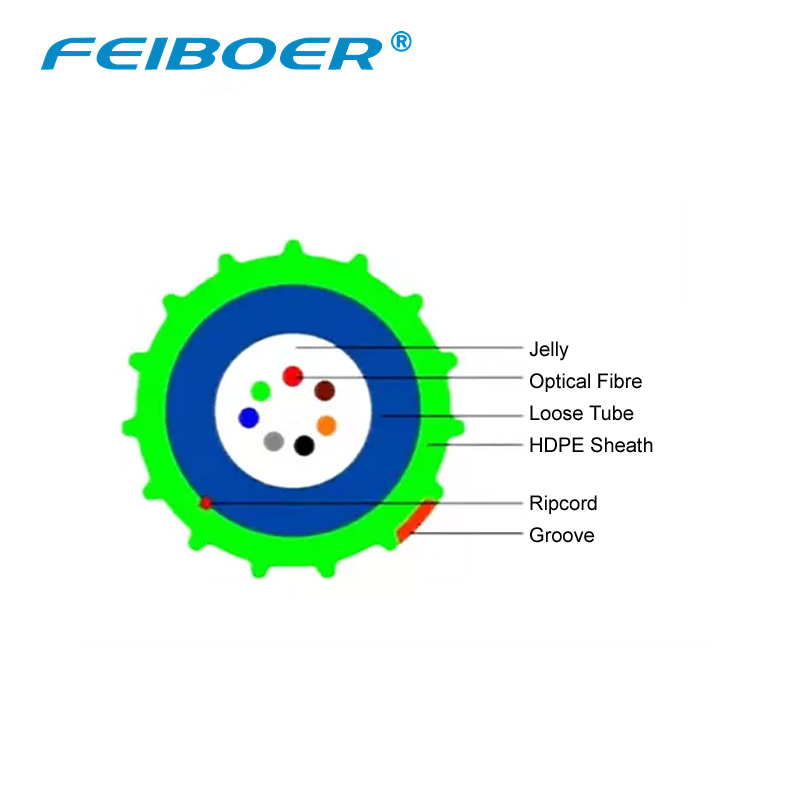

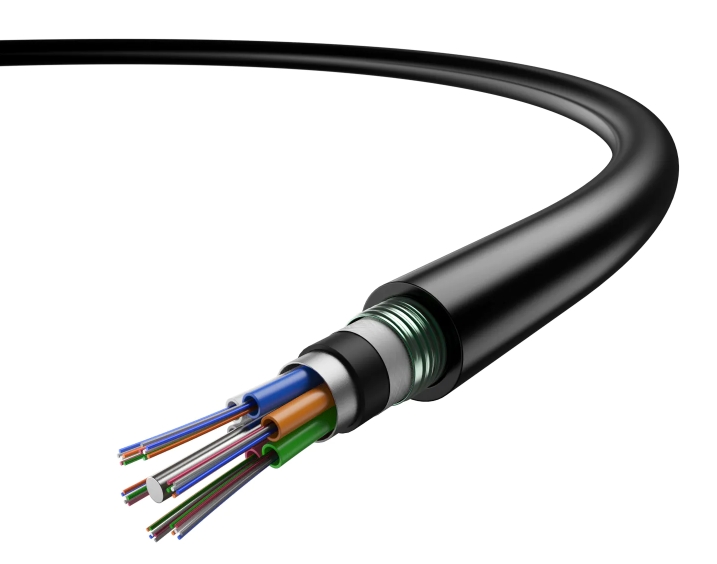

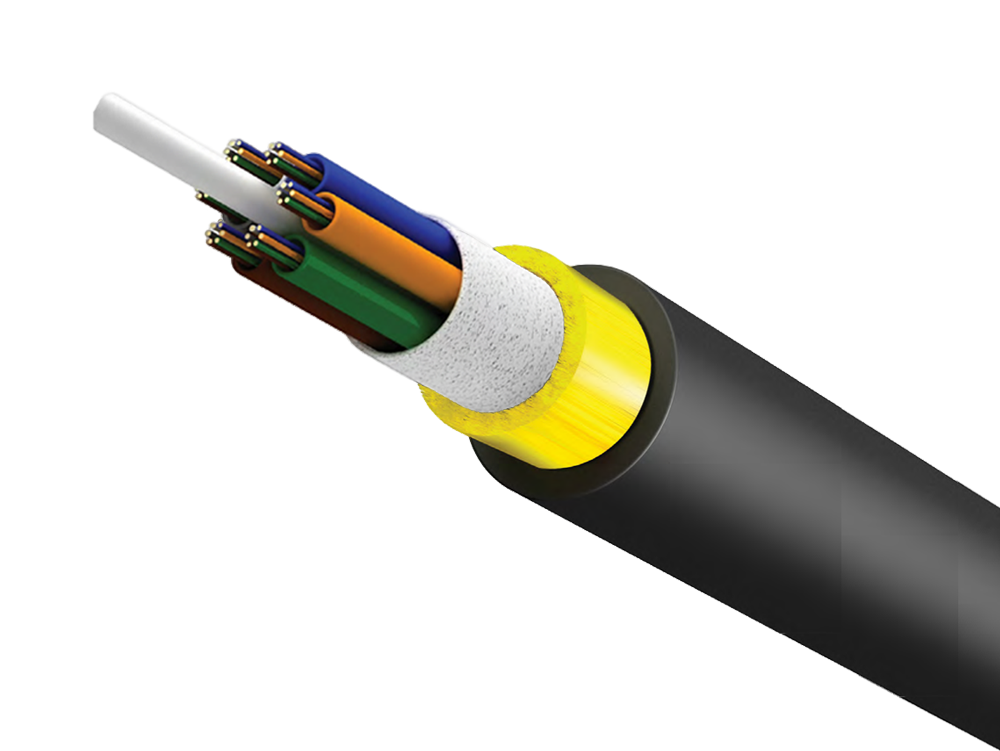

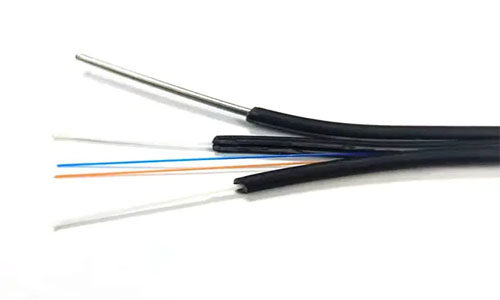

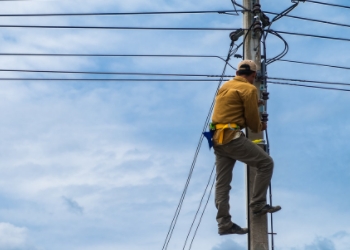

The Single Jacket ADSS Large Span 80M to 200M is a specific type of AllDielectric Self-Supporting (ADSS) fiber optic cable designed for longdistance aerial installations, covering spans ranging from 80 meters up to 200 meters. ADSS cable is loose tube stranded. Fibers, 250um , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. After stranded layer of aramid yarns are applied over. the cable is completed with PE or AT (anti-tracking) outer sheath.

We provide you with quality service

Technical Services

Technical services can improve the customer's sales efficiency and reduce the customer's operating costs. Provide customers with a full range of technical support to solve problems.

Financial Services

Financial services to solve the customer's financial services. It can reduce the financial risk of customers, solve the problem of coping with emergency funds for customers, and provide stable financial support for the development of customers.

Logistics Services

Logistics services include warehousing, transportation, distribution and other aspects to optimize customer logistics processes, inventory management, delivery, distribution and customs clearance.

Marketing Services

Marketing services include brand planning, market research, advertising and other aspects to help customers improve brand image, sales and market share. Can provide customers with a full range of marketing support, so that the customer's brand image can be better spread and promote.

Talk to our team today

We take pride in providing timely, reliable and useful services

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

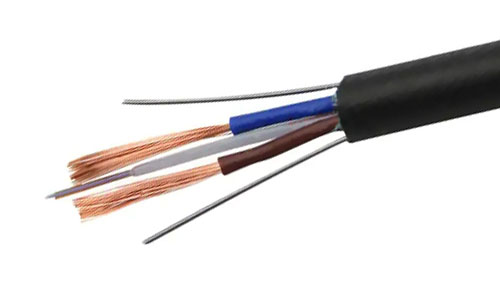

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

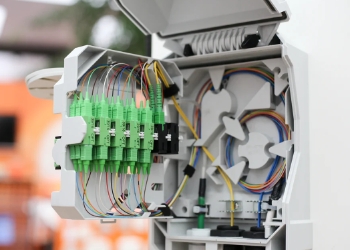

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs