Underground & Pipeline Fiber Optic Cable

Technological advancement has brought about a revolution in the world of telecommunications, paving the way for faster internet speeds.Underground fiber optic cables are responsible for allowing this increased speed by facilitating faster data transmission over long distances.These underground cables have become essential to most businesses as they enable them to send and receive information quickly and securely.

1. Stronger Performance: Underground fiber optic cable are less prone to signal interference than traditional copper wires that rely on electricity for transmission. This makes them ideal for long-distance connections, as well as for high bandwidth applications like streaming video and audio.

2. Increased Capacity: With fiber optic lines, companies can simultaneously send large amounts of data between two locations without worrying about data loss or signal degradation from external factors such as electrical interference or weather conditions.

3. Cost Efficiency: In the long run, companies save more money by installing an underground fiber optic cable rather than expensive copper wires. Additionally, installation and maintenance costs over time tend to be much lower than traditional cabling solutions since these cables tend to last longer and require fewer repairs due to their improved hardiness in extreme environmental conditions such as rain, snow and heat waves.

4. Durability: One of the most attractive aspects of fiber optic cabling is its robust construction and durability over time-this means that companies don't have to worry about frequent modifications & re-installations as with traditional copper wiring solutions which can become damaged after even a small shift in terrain or ground movements (like an earthquake). Buried deep beneath the earth's surface ensures constant protection from any external factors that would otherwise cause disruption in service.

5. Reduced Risk of Human Interference: Burying your network underground minimizes the chances that an unauthorized person could physically cut through it or gain access to it-greatly reducing the risk of intentional sabotage from hackers or other malicious individuals who may attempt to cause disruption or stealing confidential data/information stored within it.

-

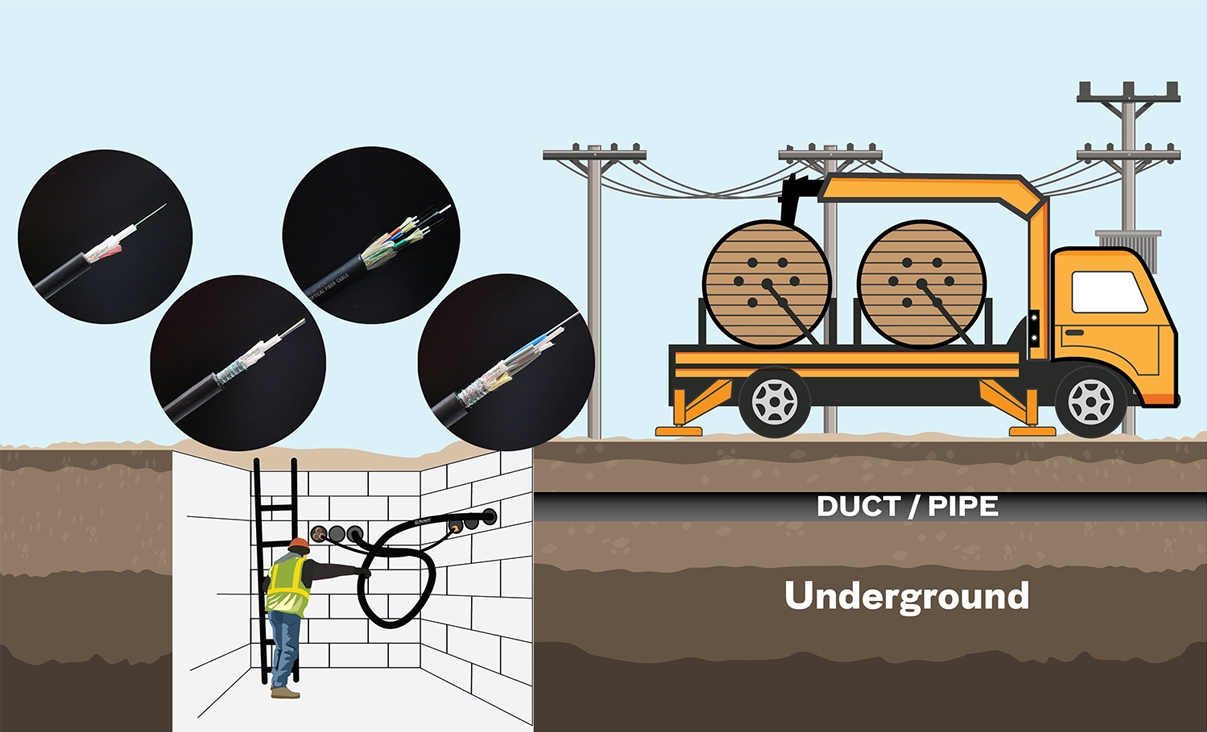

How Deep Does Fiber Optic Cable Need to be Buried?Conduits are used to bury fiber optic cable, which is typically done between 3 and 4 feet down, or 36 and 48 inches underground. Aminimum depth of 42 inches is frequently specified in fiber optic cable installation agreements, though some environments consider thel even deeper placement of the conduit.

How Deep Does Fiber Optic Cable Need to be Buried?Conduits are used to bury fiber optic cable, which is typically done between 3 and 4 feet down, or 36 and 48 inches underground. Aminimum depth of 42 inches is frequently specified in fiber optic cable installation agreements, though some environments consider thel even deeper placement of the conduit. -

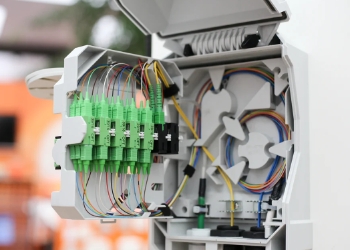

Does Underground Fiber Optic Cable Need to be in a Conduit?It is recommended that underground fiber optic cables are installed in a conduit to protect them from environmental hazards andmaintain their integrity.

Does Underground Fiber Optic Cable Need to be in a Conduit?It is recommended that underground fiber optic cables are installed in a conduit to protect them from environmental hazards andmaintain their integrity. -

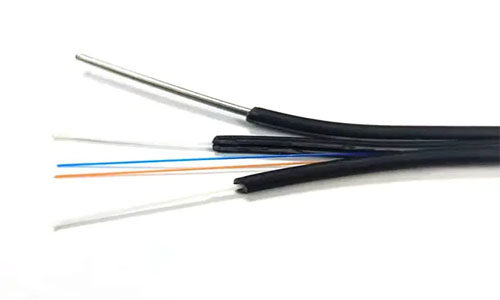

Can Underground Fiber Optic Cable be buried directly in the ground?Yes, If the cables are buried directly, they are either plowed in or buried in a trench. Please review our Direct Buried Cable InstallationGuide. .Outdoor fiber cables with steel armor are the most typical cables used for direct burial.

Can Underground Fiber Optic Cable be buried directly in the ground?Yes, If the cables are buried directly, they are either plowed in or buried in a trench. Please review our Direct Buried Cable InstallationGuide. .Outdoor fiber cables with steel armor are the most typical cables used for direct burial.

01

Ready to learn more?

Nothing is better than holding it in your hand! Click on the right

to send us an email to learn more about our products.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

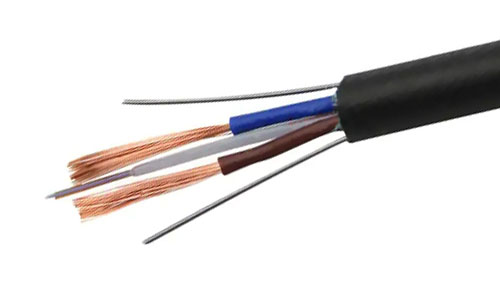

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

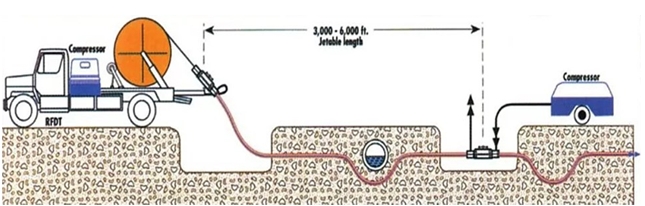

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs