OPGW Installation Procedure

Contact us for more sample, According to your needs, customize for you.

inquiry nowOPGW Installation Procedure

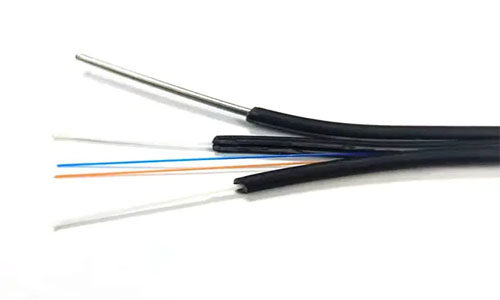

OPGW cable, also known as optical fiber composite overhead ground wire. The optical fiber is placed in the ground wire of the overhead high-voltage transmission line and installed on the top of the transmission line tower to form the optical fiber communication network on the transmission line. This structural form has the dual functions of the ground wire and communication, and is generally called OPGW optical cable.

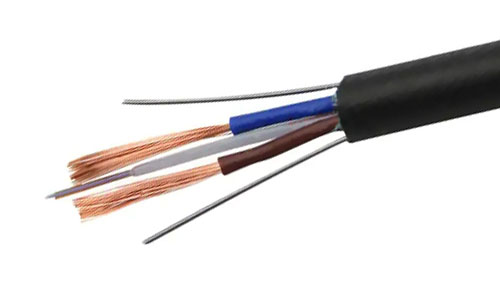

OPGW cable is wrapped with metal wire, so that the cable is more reliable, stable and firm, because the overhead ground wire and cable are combined into one, compared with the use of other ways of cable, both shorten the construction period and save construction costs. In addition, if the OPGW made of aluminum-covered steel wire or aluminum alloy wire is used, it is equivalent to setting up a good conductor overhead ground wire, which can receive many benefits such as reducing the latent power supply current of the transmission line, reducing the power frequency overvoltage, and improving the interference and dangerous impact of the power line on the communication line.

OPGW is suitable for high-voltage lines exceeding 110kv, and the spacing is large (generally above 250M); Easy to maintain, easy to solve the problem of line crossing, its mechanical characteristics can meet the line crossing; The outer layer of OPGW is metal-armoured, which has no effect on high voltage corrosion and degradation. OPGW must be cut off during construction, and the loss of power outage is large, so OPGW should be used in the new high-voltage lines above 110kv; The fiber is made of glass fiber, which is fragile and brittle.

During the construction process, OPGW should be prevented from being pulled, bruised, sprained, crushed, broken, and the cable should be smoothly pulled without being squeezed.

OPGW Installation Quality Control Points

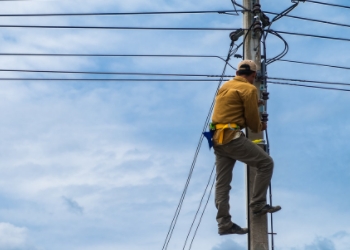

1. OPGW cable erection is similar to a power line, when erection, the original transmission line must be outage operation, prohibited in the wind, thunderstorms, cold and heat and other harsh climate construction. The bending radius of the cable should be above 0.5m.

2. The construction should avoid the cable tangled with each other, to avoid the cable outer stranded layer damage. Dynamic bending can not be less than 40 times the cable diameter, that is, in the construction to ensure that there is at least 600mm bending radius, OPGW cable can not be twisted.

Special personnel shall be assigned to monitor the crossing of major traffic routes, communication lines, power lines, etc. The cable must be controlled at a safe height to avoid collision or rolling of the cable by motor vehicles, endangering the safety of the cable or personnel.

3. OPGW cable erection to the ground crossing distance requirements: unmanned area, OPGW left the ground more than 3m; Pedestrian roads and roads with sparse traffic, the OPGW is more than 5m off the ground; Highways and railways, OPGW above the ground 7.5m.

4. In the construction process, pay attention to the protection of the outer layer of stranded wire. The outer aluminum clad steel wire or aluminum alloy wire is the carrier of overcurrent and lightning strikes, such as injury will have long-term risks to the line. Check the pulley for burrs; Do not throw or drop optical cables; Use rubber casing for protection when using wire lifter. OPGW cable tray is placed on the pay-off rack or cable tray car with rotating shaft, and the distance between the cable tray and the center of the tension machine should be guaranteed to be 5-8m.

5. Every day should ensure that the construction of a single disk of optical cable is completed, if not overnight or long time, must use nylon rope to fix the OPGW cable on the pulley, to prevent the optical cable sliding and fatigue damage to the optical fiber contact point with the pulley. At the same time, the traction rope and optical cable should be temporarily anchored at the traction end and the tension end respectively. The relaxation degree of the cable between the anchor line point of the tension end and the tension machine is appropriate to relieve the tension of the tension machine. Can not be too slack, cable must not mop the floor.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

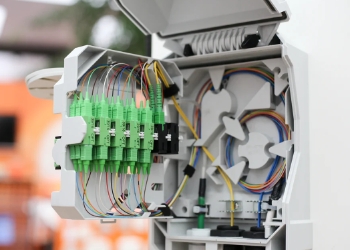

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs